MECANIZADOS CARRAZCO

About Us

Our Company

Mecanizados Carrazco

Description:

With over 25 years of experience in the industry, we are a family-owned business specializing in the manufacturing of spare parts, components, and machined parts.

Additionally, we are a valuable resource for companies needing immediate solutions in supplying spare parts or repairing components to maintain their production line. We offer spare parts built to plan or through reverse engineering, creating the layout and solving part replacements.

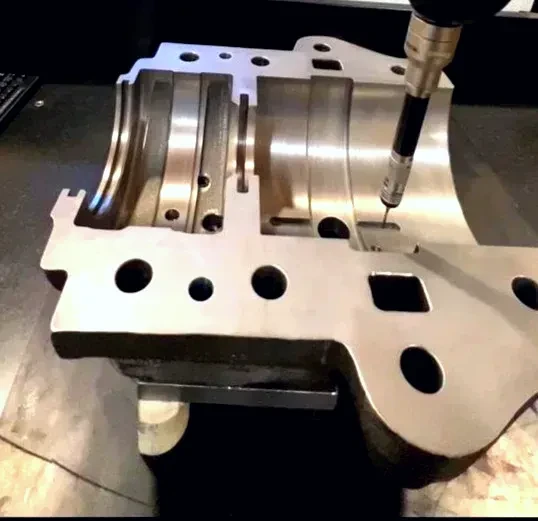

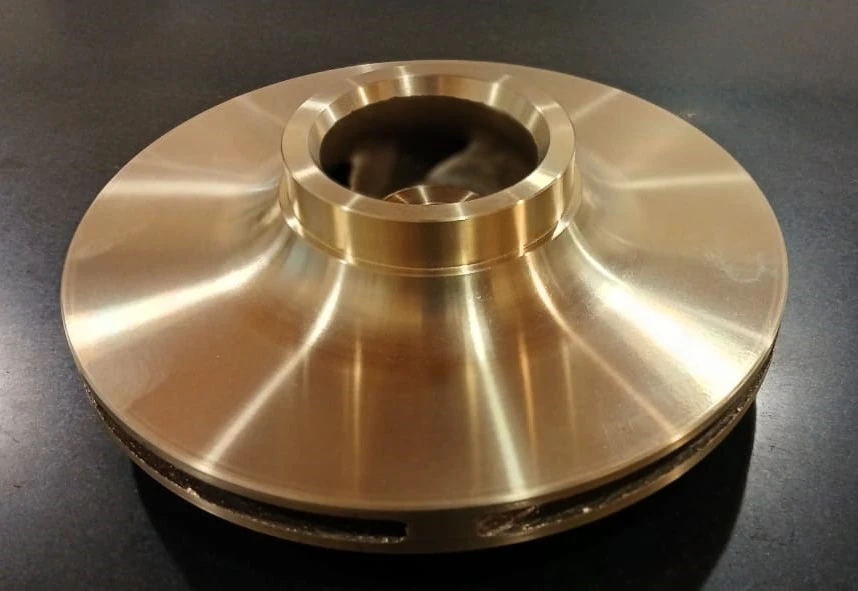

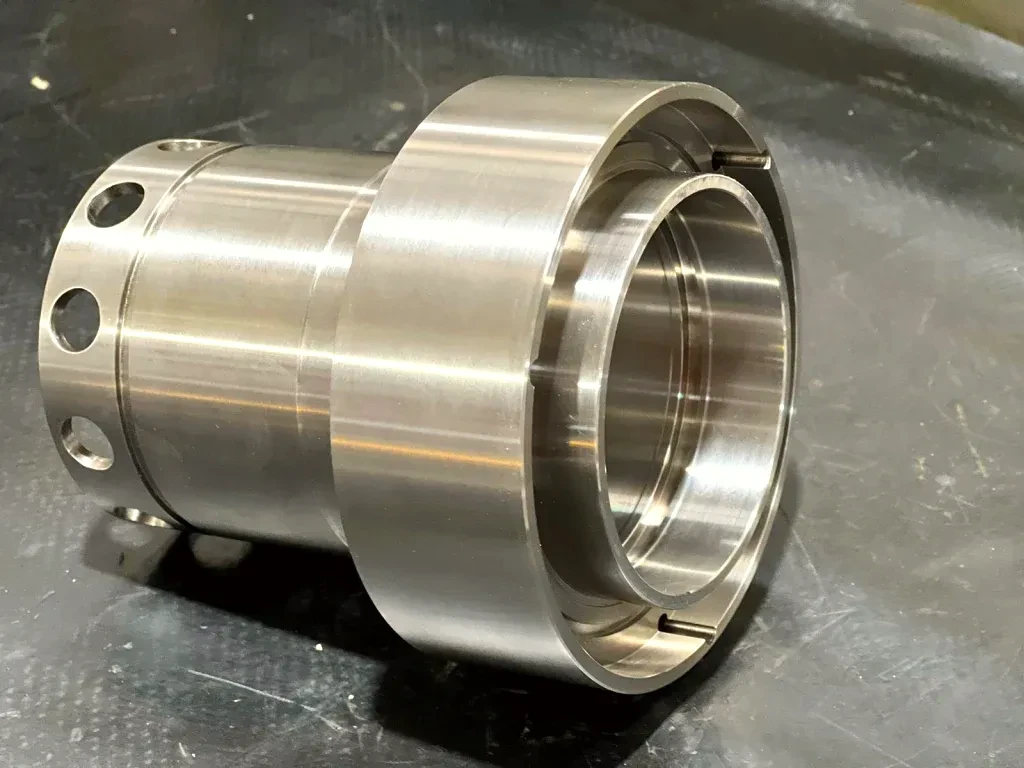

We specialize in manufacturing revolution parts, with milling on different planes, segmented split parts through chip removal or EDM (Electrical Discharge Machining).

Our commitment is to provide our customers with efficient and personalized solutions to meet their needs and expectations.

Photo Gallery

"CNC Machining / Conventional Machining / Metrology Laboratory

Operating Capacity

MULTITASKING 'MAZAK' Integrex mod. J-400 U1200

. 5-axis Machine

. Monday to Friday, 24 hours

MAZAK SQT 28M

. 5-Axis Machining Capabilities

MAZAK, VTC 16A

· Control Mazatrol 640M

"We also have...

Two automatic band saws (PLC), of national origin, brand Delle Grazie

· Maximum cutting diameter 500 mm

Ver másAn EDM penetration machine Maximart E.D.M, of Taiwanese origin

· Power 60 AMP

Wire EDM machine, of Swiss origin, brand CHARMILLES, model Robofil 310

·Capacity Ø 500 x 350 x 400 mm

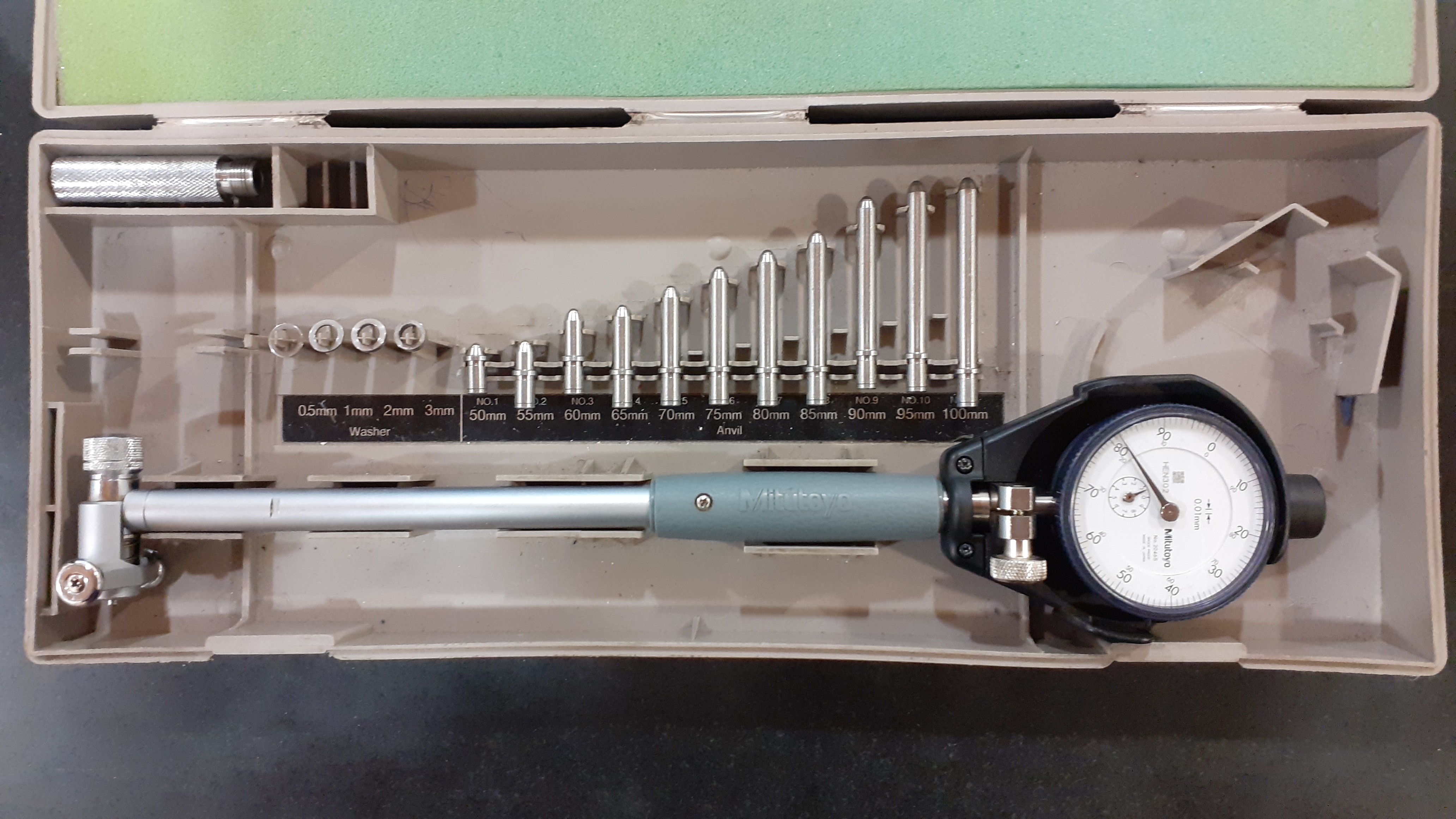

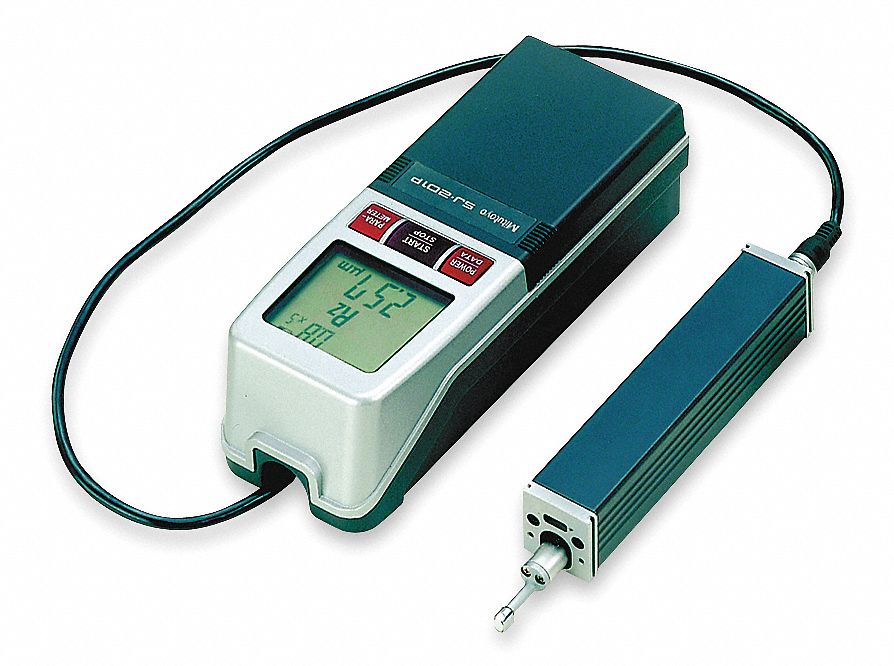

Dimensional Metrology Laboratory

Mitutoyo medición CMM

Mod. Crysta Apex S 7106. Origine Giapponese:

Contact Us!

Location

Julio Argentino Roca 1439, Maipú, Mendoza, Argentina

Hours

Monday to Friday, 24 hours.

Reservations

+54 - 0261 - 667-3215Location

Aldunate 1239 - Santiago de Chile - Region Metropolitana

Contact

+54 - 0261 - 667-3215Additional Services

At Mecanizados Carrazco, we offer a wide range of additional services to cover all your industrial needs. We have the support of leading companies in the sector to guarantee the highest quality in every job.

Welding

We provide high-precision welding solutions, utilizing the latest advancements in arc welding and MIG/MAG welding technology. Our expertise covers a variety of materials and thicknesses, adapting to the specific needs of each project.

Heat Treatment

We perform heat treatments that enhance the mechanical properties of materials, ensuring greater strength and durability in critical components. We work with processes such as hardening, tempering, and normalizing to guarantee optimal results.

Metallurgical Services

We have the support of metallurgical companies that enable us to carry out complex work in the manufacturing and repair of parts, as well as supplying high-quality metal materials.

Coating Applied by Welding and Arc Spray

We offer the possibility of applying protective coatings through welding or arc spray, a technique that extends the life of components exposed to extreme conditions.

Engineering

At Mecanizados Carrazco, we offer design and optimization services for industrial processes, covering everything from technical analysis to the implementation of customized solutions. We specialize in reverse engineering, CAD design, and 3D modeling, tailoring our services to the specific needs of each project.

Non-Destructive Testing (NDT)

We conduct non-destructive testing in collaboration with specialized laboratories, ensuring that parts meet the highest quality standards without compromising their structural integrity.

Surface Treatments

We provide surface treatments such as chrome plating and the application of special coatings to enhance corrosion and wear resistance of parts.

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.jpeg)

.webp)

.webp)

.webp)

.webp)

.webp)

.jpeg)

.jpeg)